Services

A suite of tech-based fabrication services designed for speed, accuracy, and quality

Put the Westool team to work

on your complex machined and fabricated parts and components projects.

We ensure your expectations will be exceeded with cost-effective metalworking solutions that save time and build profits.

Bring us your ideas and we’ll collaborate on bringing them to life in complete confidence, protecting your IP rights on every project.

DESIGN ENGINEERING

A collaborative process using state-of-the-art 3D design software that covers every detail

TECHNICAL SOLUTIONS

A truly unique service offered by Westool! We bring years of experience to assist in troubling situations of equipment performance such as critical breakdown, poor OEE, and quality fallout. Our team will provide onsite support and critical knowledge to develop a solution that will get you up and running again.

MACHINING AND FABRICATION

Bringing your parts and components to life using a variety of materials including copper, aluminum, stainless steels, a broad ban of plastics and an array of excotic steels for tooling applications. Westool uses specialized techniques such as welding, grinding (including flat, jig, and cylindrical), general machines, wire EDM, CNC lathes, and mills to deliver superior components, assemblies, and repairs.

ASSEMBLY

Quality assemblies including laser tooling, weld assembly tooling, feed application assemblies, and one-off purpose-built assemblies for virtually any application. We complete projects on time and to your exact specifications for immediate implementation in the field.

CONSUMABLE TOOLS

Quality-built consumable tools like bending mandrels and balls, wear parts, and other consumable tools delivered to your facility.

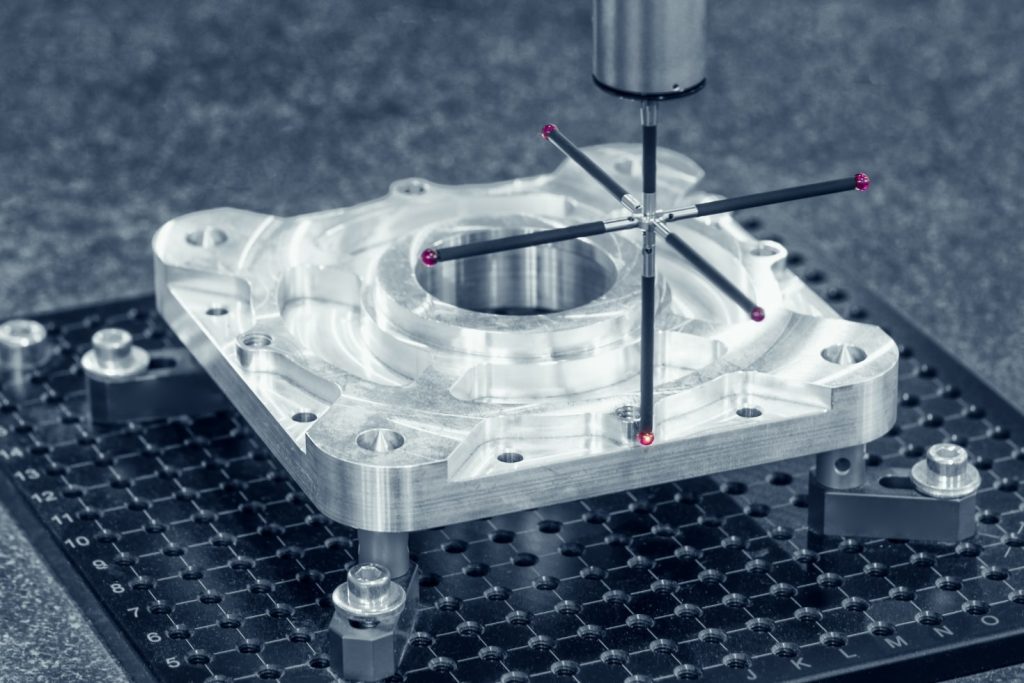

REVERSE ENGINEERING

Detailed inspection, modelling, and testing of existing components that drive innovation and new product development. This is an added benefit to repair OEM equipment that has long lead times or when you’re unable to single-source a component.

LEGACY EQUIPMENT REPAIR

Reliable, knowledgeable repair services for every model of aging equipment in the field, no matter how old or the application of the equipment.

A SHARP FOCUS ON QUALITY ASSURANCE

Westool follows a longstanding tradition of using only the best quality materials and manufacturing processes to meticulously fabricate durable, reliable products that deliver consistent performance in the field. Our products are subject to quality inspections and testing to ensure we only ship products that meet or exceed our customer expectations. Westool is an ISO 9001 certified facility.

FABRICATED BY SKILLED TALENT

All of Westool’s products are manufactured by skilled tradespeople who are among the best in their field. We focus on providing our teams with ongoing skills development to ensure they’re always up to date with the latest fabrication techniques and technology that help save you money without compromising product quality.

ACCELERATED TIME TO MARKET

Westool follows a longstanding tradition of using only the best quality materials and manufacturing processes to meticulously fabricate durable, reliable products that deliver consistent performance in the field. Our products are subject to quality inspections and testing to ensure we only ship products that meet or exceed our customer expectations. Westool is an ISO 9001 certified facility.

CONNECT WITH A WESTOOL EXPERT FOR A FAST QUOTE ON YOUR NEXT PROJECT

Find out why manufacturers trust Westool Precision Products with their machining and fabrication needs by calling 519-657-5318 or emailing info@westool.com for a project quote today! You can also provide project specs through the form below.

We look forward to working with you!